關於德曜

- HOME

- /

- ABOUT US

About De Yao Precision

Core Values

Business Philosophy

Commitment to honesty and integrity

Pursuit of sustainable management

Our customers are also our partners

At De Yao Precision, we believe that our customers are also our partners, and helping our customers succeed also means the success of Da Yao Precision, Therefore, it is our responsibility to prioritize customer’s needs and work closely together. We always look forward to building a deep and profound partnership with our customers and become the best trustworthy partner for them. CNC

We are committed to providing our customers with the best "quality and service"

Maintain a high level of corporate vitality

TRAINING

Corporate Training

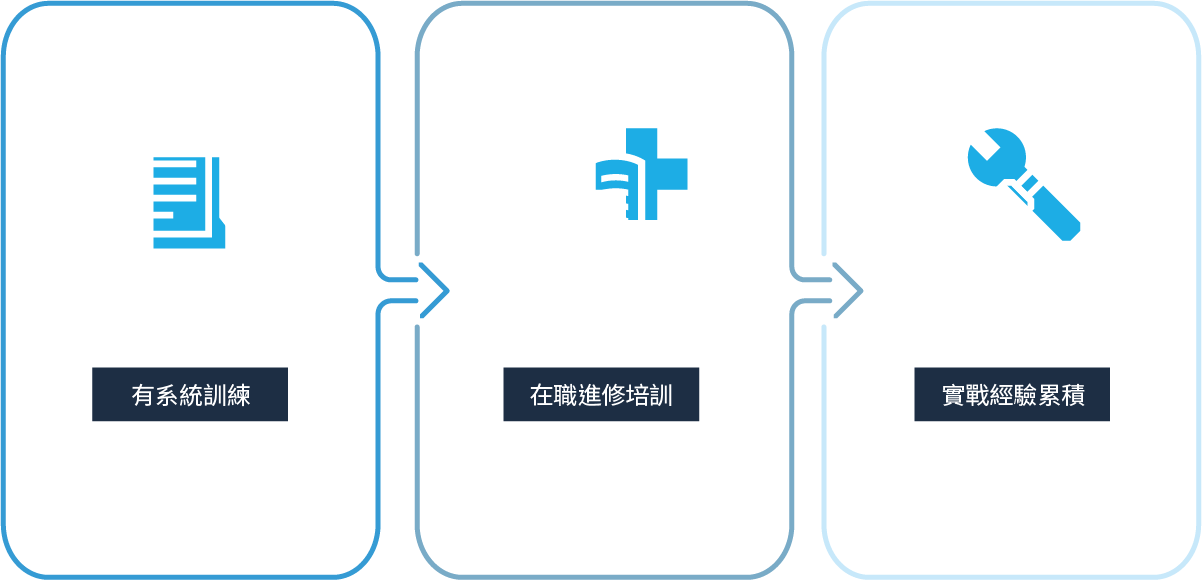

Systematic training

Employees are a company's greatest asset, yet they need training to form a solid team. Under the framework of ISO 9001 standards, De Yao Precision has been continuously improving the quality of employees and manufacturing skills in a systematic and innovative way to cultivate a strong and solid team.

On-the-job training

We hold on-the-job training from time to time to strengthen the teamwork and technical skills of our employees and to steadily improve the competitiveness of the company.

Practical experience

From practical work to learning, and then from learning to practical work, we work hard on honing basic skills, and enhance the technical experience of our staff to ensure product quality through repeated training and practical work, so that we can continue to foster assurance in the quality stability of De Yao Precision products.

TRAINING

Corporate Training

SDGs

Corporate Care

End Poverty in All its Forms Everywhere

Promote Sustained, Inclusive and Sustainable Economic Growth, Full and Productive Employment, and Decent Work for All

ENVIRONMENT

Factory Introduction

HISTORY

History of De Yao Precision

2012

Founded with computerized lathe processing capabilities. – September 2012

2015

Established De-Xin Technology Co., Ltd. -January 2015. Purchased an automatic bar feeder. -February 2015 Purchased computerized milling machines to process machine parts for electronics factories. -October 2015

2018

Automation upgrade – Introduction of Computerized Lathe with Automated Material Handling System. -June 2018

2020

Expanded production capacity and purchased additional equipment. -October 2020

2020-2

Introduction of Mitutoyo profilometer for quality control. – November 2020

2020-1

Expanded the purchase of Japanese OKUMA lathes. – June 2021

2021

Started construction of new factory plant. – November 2021

2022

Expanded production capacity and purchased additional equipment. -March 2022

2022-2

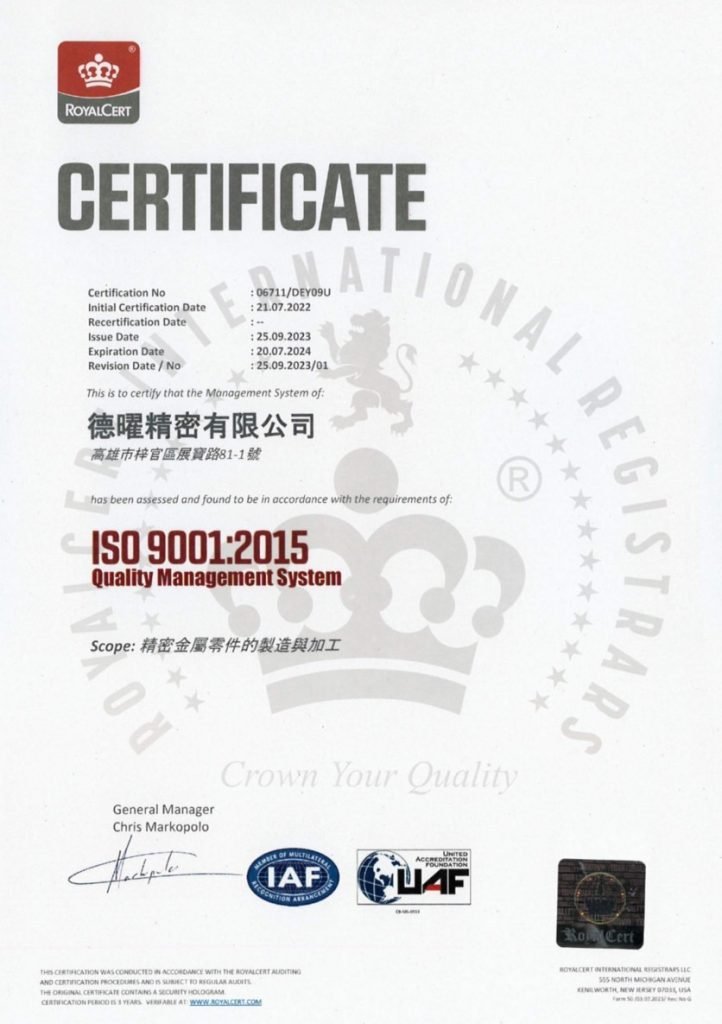

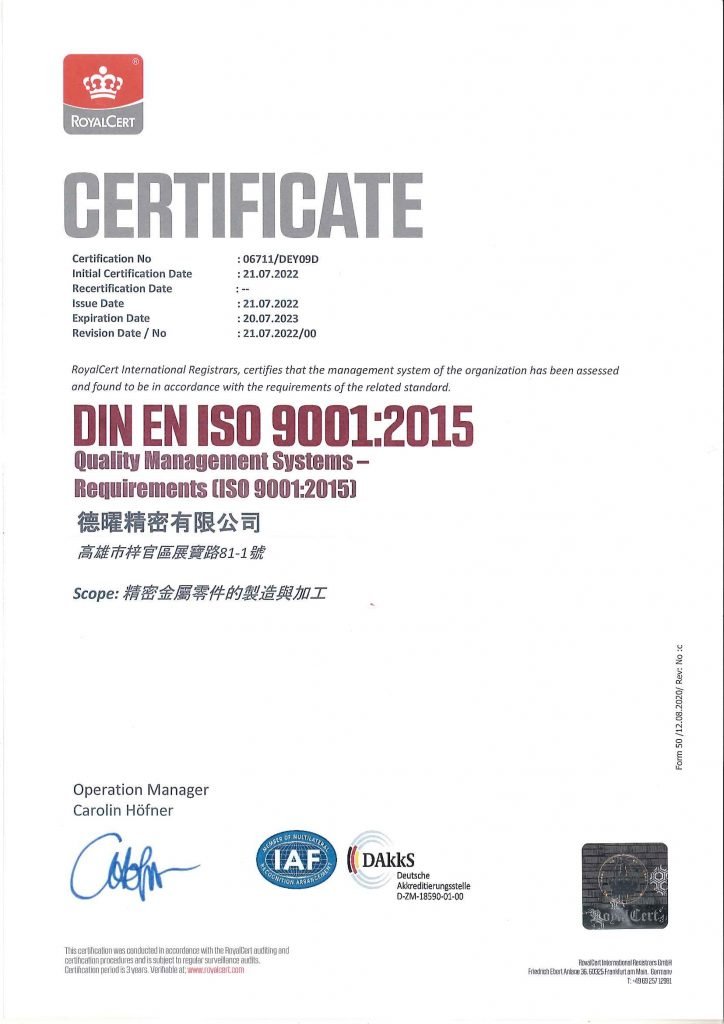

Obtained ISO 9001 international certification. -June 2022

2022

The new plant is expected to be completed. -December 2022

PATENT

Patents